Europe Top Spa & Golf

Wrought Iron Greenhouse Project

Table of Contents

- In 2017, we undertook a large-scale wought iron gzaebo project for one of Europe’s top spa and golf resorts, located in Northern Ireland. The custom-designed greenhouse measures 20 meters in length and 6 meters in width. It was completed and delivered in 2018, and is now fully installed and available for use by resort guests.

- This 4-star Spa & Golf Resort features a luxury spa and an award-winning restaurant. The project was commissioned by the resort manager, who has over 40 years of experience in international procurement. Before finalizing the order, he held three focused meetings with our designer, sales team, and company director.

- Over a three-month period, we carefully discussed all aspects of the project, including government approvals and technical details. After thorough consideration, he chose us to manufacture the greenhouse for the resort.

- Even during the COVID-19 pandemic, we continued to provide remote support to ensure the successful installation of the greenhouse. Thanks to close communication and detailed guidance, the customer was able to complete the installation smoothly despite the global challenges.

Greenhouse

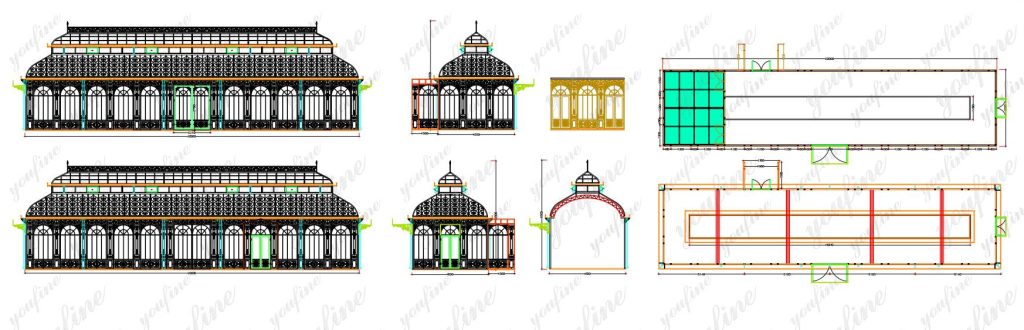

Drawing

Drawing

Greenhouse

Drawing

- For certain greenhouse projects, approval from the local government is required. Our professional design team provides clients with detailed structural data, including gravity load and wind load calculations, to ensure safety and compliance with regulations.

- All relevant data is carefully calculated to eliminate potential risks. We consistently offer expert support to help our clients obtain the necessary permits and approvals.

- For projects that do not require government approval, we still provide detailed design drawings before production begins.

- This ensures the final product matches the client’s exact specifications and expectations. Our commitment to precision and client satisfaction is reflected in every step of the process.

National Standard

Materials

Materials

National Standard

Materials

- The YouFine wrought iron gazebo features a robust galvanized steel frame and premium glazing, reflecting YouFine’s commitment to durability, quality, and craftsmanship.

- Structural components use corrosion-resistant galvanized steel pipes that are meticulously polished to remove surface oils and oxidation; all raw materials come from certified steel manufacturers meeting strict national standards.

- After polishing, every part receives an electrostatic primer coat and a hot-dip galvanizing treatment to maximize rust resistance and ensure a long-lasting, peel-resistant finish.

- All glass panels are precision-cut by certified suppliers to exact dimensions, and clients can choose from a variety of 3C-certified options—from single-pane and insulated double-pane to laminated, UV-blocking laminated, and high UV-protection glass—to suit specific performance needs.

- The gazebo roof is built with transparent double-glazed tempered glass panels that are laminated for extra strength and weather resistance, capable of withstanding heavy snow loads while flooding the interior with natural light.

Greenhouse

Pattern Design

Pattern Design

Greenhouse

Pattern Design

- Our artisans possess extensive experience in iron craftsmanship, blending traditional skills with modern technology.

- We utilize advanced CNC cutting machines to ensure precise material shaping, and employ state-of-the-art forging and bending equipment to create intricate three-dimensional patterns.

- Whether it’s elegant curves or complex floral motifs, we can fully meet our clients’ design requirements.

- For highly detailed custom designs, we also offer casting services to bring even the most elaborate concepts to life.

Trial

Installation

Installation

Trial

Installation

- Before painting, our skilled craftsmen carry out a full trial assembly to ensure the greenhouse is structurally stable and safe.

- During this process, any components that require adjustment are carefully refined to ensure a perfect fit.

- Our team then documents the assembled structure with detailed photos and videos, which are shared with the client for review.

- At the same time, every detail is thoroughly inspected to guarantee that the final product delivered to our customers meets the highest standards of quality and craftsmanship.

Painting

Process

Process

Painting

Process

- For the coloring process, we use a combination of plastic spraying and high-temperature paint to ensure long-lasting, weather-resistant finishes.

- Every part of the greenhouse—including the joints and connection surfaces—is treated with anti-rust coating to prevent corrosion over time.

- Finally, the desired color, such as green in this project, is carefully hand-sprayed to meet the client’s aesthetic preferences.

- To ensure harmony with the resort’s overall style, YouFine custom-mixes the most suitable color, creating a seamless and elegant visual effect.

Product

Packaging

Packaging

Product

Packaging

- Before shipment, each iron product needs to be individually wrapped with film and fixed with strong wooden stakes to avoid collision during long-term transportation.

- Each wooden crate also has a step-by-step drawing on the outside to indicate the component number of the pavilion.

Installation

Instructions

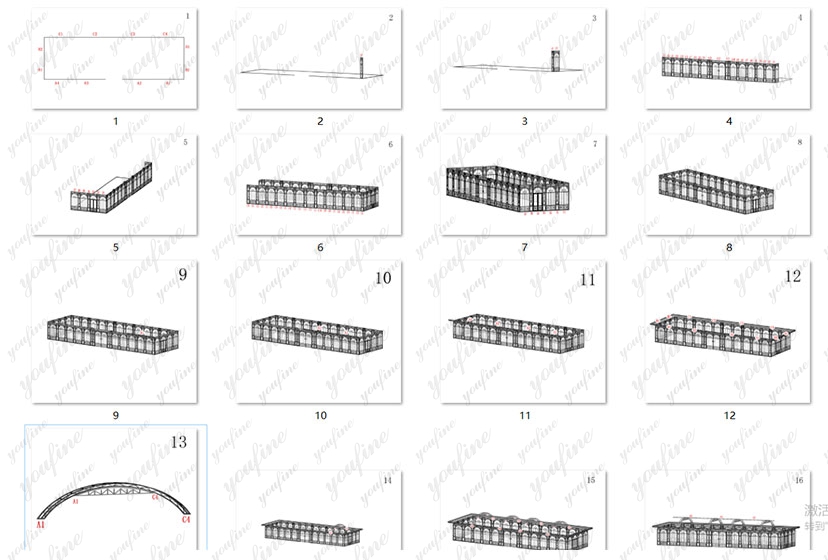

Instructions

Installation

Instructions

- For installation, our design team provides clear, step-by-step graphical instructions, with each component labeled with a corresponding number to ensure quick and accurate assembly.

- The greenhouse structure features bolt connections and standardized interfaces, allowing regular workers to complete the installation efficiently by simply following the drawings—no specialized tools are required.

- This streamlined approach improves installation efficiency by up to 50%.

- According to the detailed installation drawings we provided, the customer was able to complete a flawless installation.

- Especially in today’s global COVID-19 environment, we continue to offer comprehensive after-sales technical support, including real-time video guidance, to ensure that even without overseas installers, our customers can complete the project with full confidence and peace of mind.

Customer

Feedback

Feedback

Customer

Feedback

Contact YouFine at Any Time for Professional Services

Note: All your information is used for communication between us and you, and no personal information will be leaked.